News

SINO-FOUNDRY—professional refractory manufacturer

Features of Silica ramming mass

2022-11-23

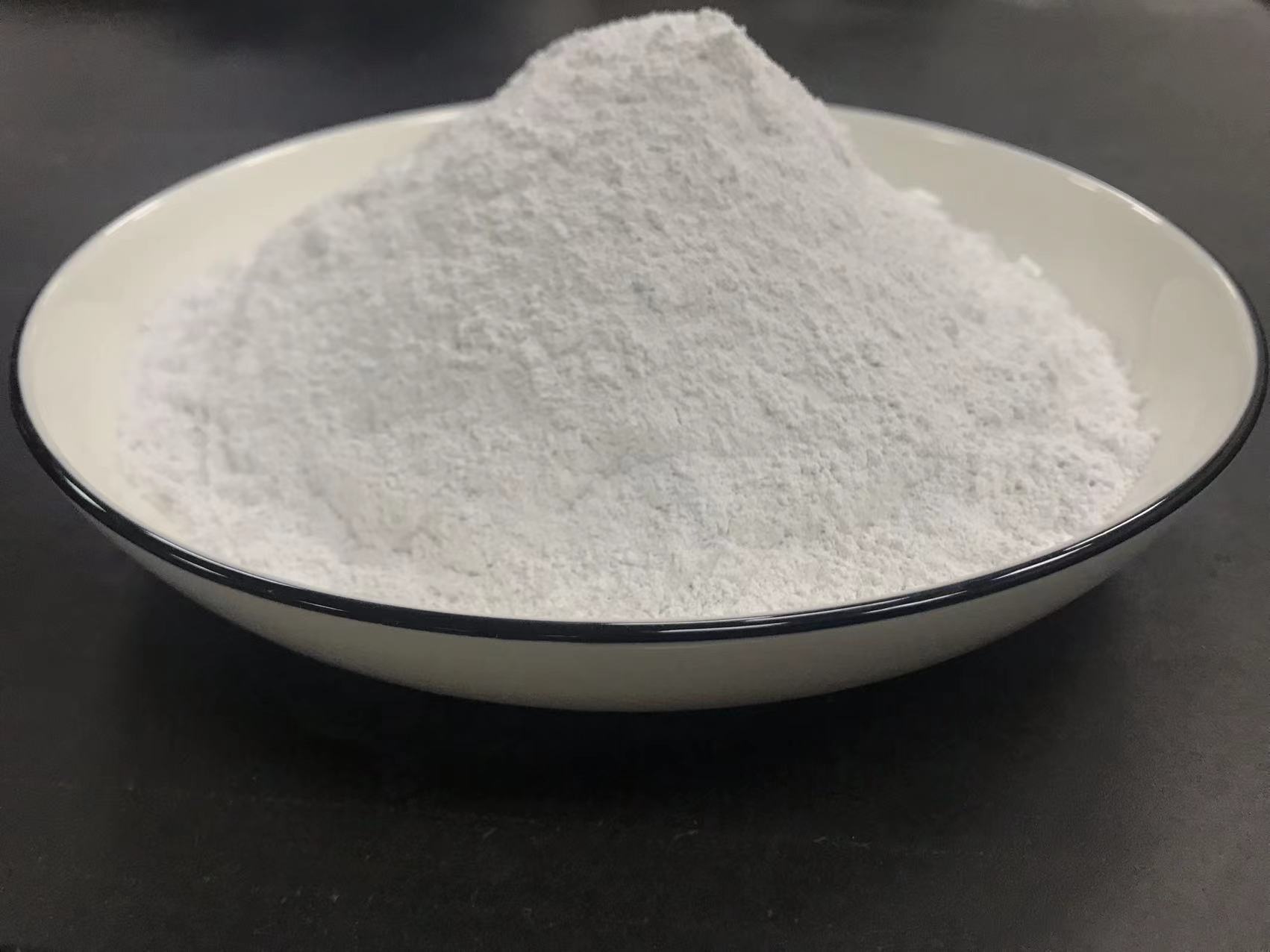

Silica ramming mass refractory raw materials are high-purity microcrystalline quartz sand, powder, high-temperature sintering agent and mineralizer, which are mixed into granular and powdery materials. They often contain appropriate binders and are made by mixing and kneading. They are loose. It must be constructed by strong ramming during construction, so it is called ramming material. Silica ramming mass has a high conversion rate of α-phosphorous quartz after being sintered in a furnace due to the function of mineralizers, so the drying time is short, and it has good volume stability, thermal shock stability and high high temperature strength. The backing remains in a constant loose layer during use.

Silica ramming mass features:

1. Silica ramming mass has the advantages of good stability, good slag resistance, and long furnace life. It is the best charge for melting bronze, red copper, and cupronickel in industrial frequency furnaces and intermediate frequency furnaces.

2. Compared with other unshaped refractory materials of the same material, the ramming material is dry or semi-dry and loose, and most of them have no cohesiveness before forming, so only strong ramming can obtain a dense structure.

3. Most ramming materials made of temporary binders have low room temperature strength before sintering, and the strength can be significantly improved only when heated to sintering.

4. For those made of chemical binders and carbon-containing binders, after proper heat treatment, the binders can be strongly bonded or the carbon-containing compounds in them can be coked to obtain high strength.

5. The refractoriness and melt erosion resistance of Silica ramming mass can be obtained by selecting high-quality refractory raw materials, using correct proportioning and strong tamping. Compared with castables and plastics, it has higher stability and corrosion resistance at high temperatures.

6. Silica ramming mass has good chemical stability, erosion resistance, abrasion resistance, peeling resistance and thermal shock resistance.

Related News

2021-09-29

The manufacturer of Refractory castable cement tells you a kind of granular and powdery material made of refractory materials with a certain amount of binder. With high fluidity, it is suitable for unshaped refractory materials formed by casting.

WeChat public account

View mobile website

Address : No. 99, Yiqing Road, Gaozi Street, EconomicDevelopment Zone, Dantu District, Zhenjiang City

Fax : +86-511-85683066

E-mail : sales@sfr168.com

Website : https://www.sfr168.com

Copyright©2023 Sino-Foundry Refractory(Jiangsu) Co.,Ltd. Powered by:www.300.cn

Copyright©2023 Sino-Foundry Refractory(Jiangsu) Co.,Ltd.

IPV6 | SEO | Cloud Information