News

SINO-FOUNDRY—professional refractory manufacturer

The temperature of the dry vibrating material of the intermediate frequency furnace can reach 2000 degrees

2021-12-22

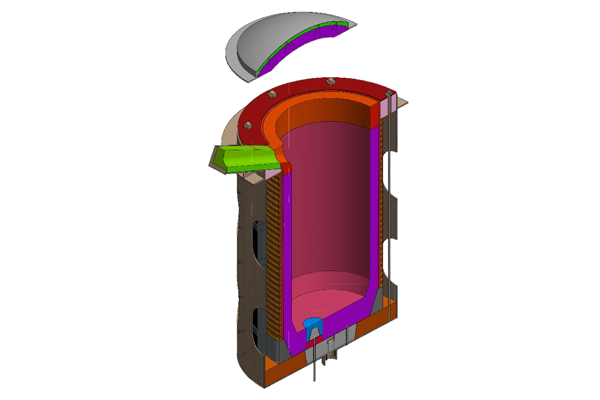

The dry vibrating material of the intermediate frequency furnace is made by mixing refractory aggregates, powders, binders, admixtures with water or other liquids with a certain gradation, and is constructed by ramming (manual or mechanical).

The dry vibrating material of the intermediate frequency furnace is made by mixing refractory aggregates, powders, binders, admixtures with water or other liquids with a certain gradation, and is constructed by ramming (manual or mechanical). The dry vibrating material of the intermediate frequency furnace It is an unshaped refractory that can be hardened under heating above normal temperature.

The granular and powdered materials of the intermediate frequency furnace dry vibrating material have high volume stability, compactness and corrosion resistance, and some are also insulating. Compared with other unshaped refractory materials of the same material, the intermediate frequency furnace dry vibrating material is dry Or semi-dry, loose, compact structure is obtained by hard ramming. When heated to the sintering temperature, the combined body has strength and is mainly used for the parts that are in direct contact with the melt.

The temperature of the dry vibrating material of a good intermediate frequency furnace can reach 2000 degrees. It is widely used in continuous and intermittent operating environments of non-ferrous and ferrous metals, as well as in coreless intermediate frequency furnaces and cored induction furnaces to melt gray cast iron and ductile iron. , Forgeable cast iron, vermicular graphite cast iron and cast iron alloys, melting carbon steel, alloy steel, high manganese steel, tool steel, heat-resistant steel, stainless steel, melting aluminum and its alloys, melting copper alloys such as copper, brass, cupronickel and bronze Wait.

The dry vibrating material of the intermediate frequency furnace can be built directly without stirring during use. It has no slag, no cracks, no failure when damp, convenient repair of the furnace, and corrosion resistance, especially the characteristics of improving the age of the furnace, which can significantly improve economic benefits .

Related News

2024-11-05

Zhongzhu New Materials Industry sincerely invites you to participate in the 24th International Forum and Exhibition on Recycled Metals.

WeChat public account

View mobile website

Address : No. 99, Yiqing Road, Gaozi Street, EconomicDevelopment Zone, Dantu District, Zhenjiang City

Fax : +86-511-85683066

E-mail : sales@sfr168.com

Website : https://www.sfr168.com

Copyright©2023 Sino-Foundry Refractory(Jiangsu) Co.,Ltd. Powered by:www.300.cn

Copyright©2023 Sino-Foundry Refractory(Jiangsu) Co.,Ltd.

IPV6 | SEO | Cloud Information