Intelligent Equipment

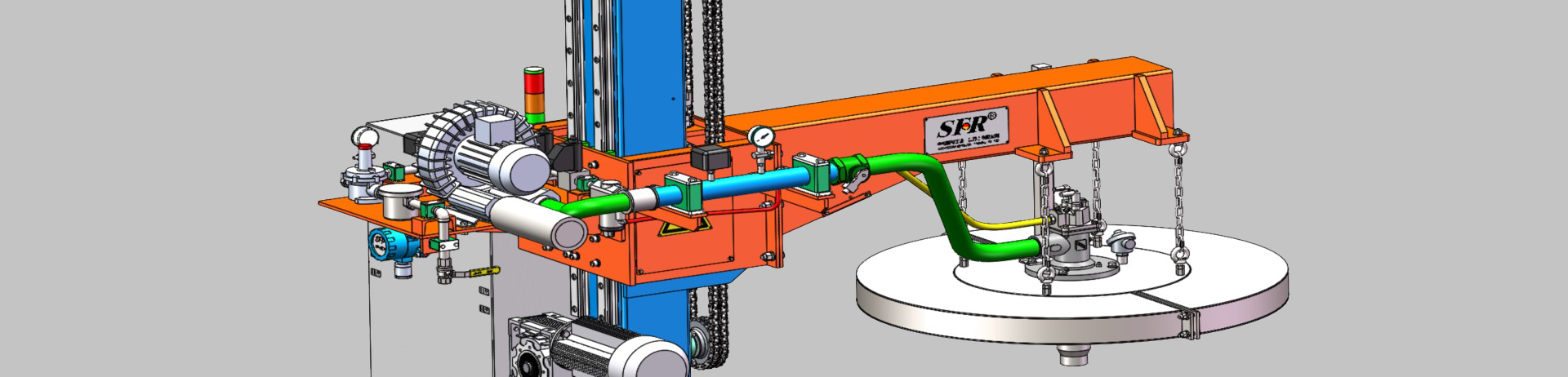

Channel furnace/Pressure pour furnace

Channel furnace and pressure pour furnace are two types of specialized equipment used in the casting of metal parts. These furnaces play a critical role in the casting process by melting and holding metal alloys at precise temperatures and conditions to achieve the desired properties and characteristics.

Channel furnace, also known as a trough or spout furnace, is a tilting furnace used for melting and pouring nonferrous metals such as aluminum, brass, and copper. The furnace is designed with an inclined channel that directs the molten metal into molds or casting machines. Channel furnaces have a high production rate and are often used in foundries and die-casting operations.

Pressure pour furnace, also known as a tilt-pour furnace, is used for the high-pressure casting of non-ferrous metals such as aluminum, copper, and zinc. The furnace is designed to melt the metal and transport it into a holding tank, where a plunger applies pressure to force the molten metal into a mold. Pressure pour furnaces offer precision control over the casting process, resulting in high-quality parts with excellent surface finish and structural integrity.

Both types of furnaces require specialized knowledge and expertise to operate efficiently and safely. The proper selection and use of refractory materials are critical in maintaining the furnace's performance and durability. Additionally, regular maintenance and inspections help ensure the furnace's safe operation and prevent equipment failure and production downtime.

In summary, channel furnace and pressure pour furnace play a crucial role in the casting process, providing efficient and reliable equipment for melting and pouring non-ferrous metals. The appropriate selection and maintenance of these furnaces are critical to their safe and efficient operation, delivering high-quality parts with excellent properties and performance.

Channel furnace, also known as a trough or spout furnace, is a tilting furnace used for melting and pouring nonferrous metals such as aluminum, brass, and copper. The furnace is designed with an inclined channel that directs the molten metal into molds or casting machines. Channel furnaces have a high production rate and are often used in foundries and die-casting operations.

Pressure pour furnace, also known as a tilt-pour furnace, is used for the high-pressure casting of non-ferrous metals such as aluminum, copper, and zinc. The furnace is designed to melt the metal and transport it into a holding tank, where a plunger applies pressure to force the molten metal into a mold. Pressure pour furnaces offer precision control over the casting process, resulting in high-quality parts with excellent surface finish and structural integrity.

Both types of furnaces require specialized knowledge and expertise to operate efficiently and safely. The proper selection and use of refractory materials are critical in maintaining the furnace's performance and durability. Additionally, regular maintenance and inspections help ensure the furnace's safe operation and prevent equipment failure and production downtime.

In summary, channel furnace and pressure pour furnace play a crucial role in the casting process, providing efficient and reliable equipment for melting and pouring non-ferrous metals. The appropriate selection and maintenance of these furnaces are critical to their safe and efficient operation, delivering high-quality parts with excellent properties and performance.

| Product | Al2O3 | MgO | Cr2O3 | Bulk density“ (g.cm¯³) | Maximum operating temperature (℃) |

| ALU-CAP 805 | 94.0 | 2.0 | / | 2.9 | 1800 |

| ALU-FLO 807CR | 85.0 | / | 10.0 | / | 1800 |

| ALU-RAM 801 | 90.0 | / | / | 3.1 | 1700 |

| ALU-RAM 802CR | 85.0 | / | 8.0 | 3.0 | 1700 |

| ALU-RAM 803 | 97.0 | 2.0 | / | 3.0 | 1800 |

| ALU-SEAL 808CR | / | / | 98.5 | / | 1850 |

| MAG-CAP 806 | 10.0 | 84.0 | / | 2.6 | 1800 |

| MAG-RAM 804 | 11.0 | 85.0 | / | 2.9 | 1850.0 |

WeChat public account

View mobile website

Address : No. 99, Yiqing Road, Gaozi Street, EconomicDevelopment Zone, Dantu District, Zhenjiang City

Fax : +86-511-85683066

E-mail : sales@sfr168.com

Website : https://www.sfr168.com

Copyright©2023 Sino-Foundry Refractory(Jiangsu) Co.,Ltd. Powered by:www.300.cn

Copyright©2023 Sino-Foundry Refractory(Jiangsu) Co.,Ltd.

IPV6 | SEO | Cloud Information