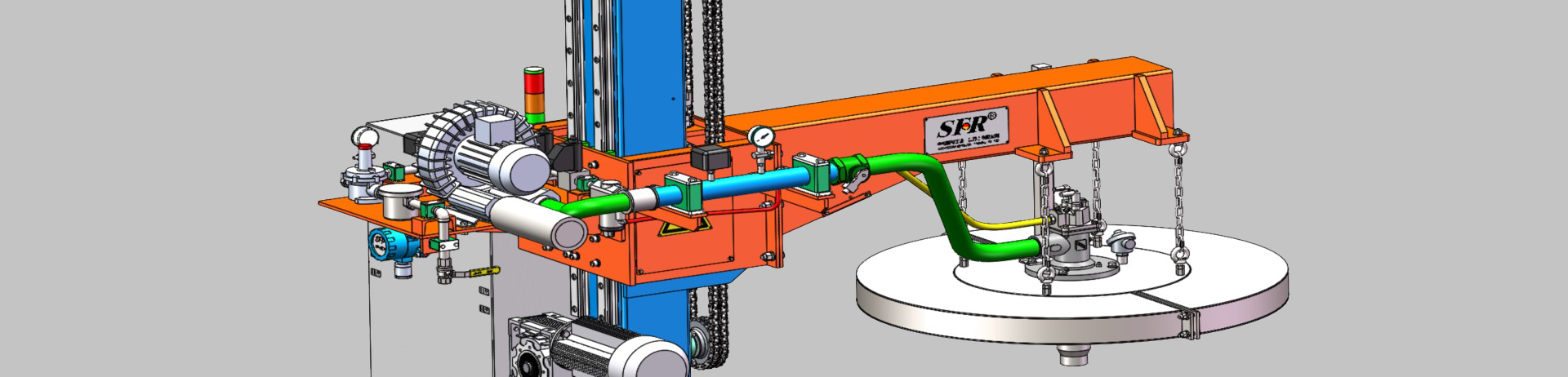

Intelligent Equipment

Dry ramming mass for copper

Dry ramming mass for copper is a specialized refractory material used in the smelting and casting of copper alloys. It is a dry material that is compressed into the furnace lining to provide high-temperature resistance and protection from chemical corrosion.

Dry ramming mass for copper is typically made from high-purity raw materials such as alumina, silicon carbide, and graphite. These materials offer excellent thermal conductivity, chemical resistance, and mechanical strength, making them ideal for use in the harsh environments found in the copper smelting and casting process.

The use of dry ramming mass for copper offers several benefits, including improved thermal and mechanical resistance, reduced energy consumption, and increased product quality. Additionally, dry ramming mass can be easily installed, and its high consistency ensures uniformity in the furnace lining, reducing the risk of defects and uneven melting.

The selection of the appropriate dry ramming mass depends on several factors, such as the desired melting rate, furnace type, and the type of copper alloy being processed. Each raw material used in the dry ramming mass production has its unique properties, such as thermal conductivity and corrosion resistance.

To ensure optimal performance, proper installation techniques and regular maintenance practices must be followed. Any failure to maintain the furnace lining can result in damage to the equipment and production downtime.

Overall, the use of dry ramming mass for copper is essential to the efficient and safe melting and casting of copper alloys and plays a crucial role in the copper industry. The selection of high-quality raw materials and proper installation techniques is essential in ensuring optimal performance and reducing the risk of equipment damage and production downtime.

Dry ramming mass for copper is typically made from high-purity raw materials such as alumina, silicon carbide, and graphite. These materials offer excellent thermal conductivity, chemical resistance, and mechanical strength, making them ideal for use in the harsh environments found in the copper smelting and casting process.

The use of dry ramming mass for copper offers several benefits, including improved thermal and mechanical resistance, reduced energy consumption, and increased product quality. Additionally, dry ramming mass can be easily installed, and its high consistency ensures uniformity in the furnace lining, reducing the risk of defects and uneven melting.

The selection of the appropriate dry ramming mass depends on several factors, such as the desired melting rate, furnace type, and the type of copper alloy being processed. Each raw material used in the dry ramming mass production has its unique properties, such as thermal conductivity and corrosion resistance.

To ensure optimal performance, proper installation techniques and regular maintenance practices must be followed. Any failure to maintain the furnace lining can result in damage to the equipment and production downtime.

Overall, the use of dry ramming mass for copper is essential to the efficient and safe melting and casting of copper alloys and plays a crucial role in the copper industry. The selection of high-quality raw materials and proper installation techniques is essential in ensuring optimal performance and reducing the risk of equipment damage and production downtime.

| Product | Al2O3 | SiO2 | MgO | Bulk density (g.cm¯³) |

Maximum operating temperature (℃) |

| ALU-RAM 122CU | 80.0 | 13.0 | / | 2.60 | 1420 |

| ALU-RAM 125CU | 80.0 | 13.0 | / | 2.60 | 1450 |

| ALU-RAM 128CU | 84.0 | 9.0 | / | 2.85 | 1300 |

| ALU-RAM 135CU | 89.0 | 3.5 | / | 3.05 | 1550 |

| SIL-RAM 120CU | 0.5 | 99.2 | / | 1.90 | 1650 |

| SIL-RAM 220CU | 0.5 | 99.2 | / | 1.90 | 1650 |

| ALU-RAM 330CU | 67.0 | 0.2 | 31.0 | 2.90 | 1600 |

| ALURAM 430CU | 84.3 | 2.4 | 11.0 | 3.15 | 1600 |

| ALU-RAM 130CU | 84.0 | 2.5 | 11.0 | 3.15 | 1550 |

| ALU-RAM 230CU | 84.0 | 2.5 | 11.0 | 3.15 | 1600 |

WeChat public account

View mobile website

Address : No. 99, Yiqing Road, Gaozi Street, EconomicDevelopment Zone, Dantu District, Zhenjiang City

Fax : +86-511-85683066

E-mail : sales@sfr168.com

Website : https://www.sfr168.com

Copyright©2023 Sino-Foundry Refractory(Jiangsu) Co.,Ltd. Powered by:www.300.cn

Copyright©2023 Sino-Foundry Refractory(Jiangsu) Co.,Ltd.

IPV6 | SEO | Cloud Information