News

SINO-FOUNDRY—professional refractory manufacturer

Introduction to the properties of refractory dry ramming mass

2022-02-18

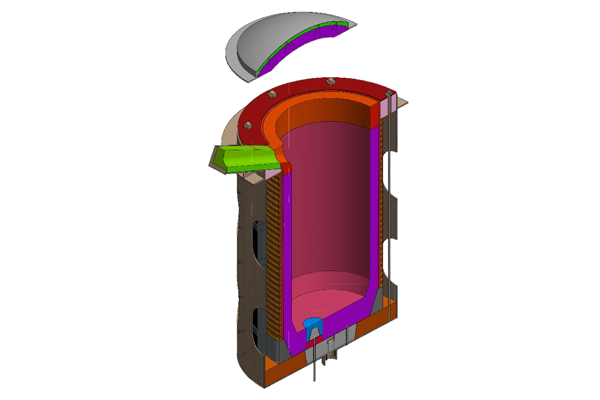

Refractory dry ramming mass is dry or semi-dry loose, most have no binder before molding, so only strong ramming can get a dense structure. The refractory dry ramming mass manufacturer tells you that most ramming materials have low room temperature strength before sintering.

Refractory dry ramming mass is dry or semi-dry loose, most have no binder before molding, so only strong ramming can get a dense structure. The refractory dry ramming mass manufacturer tells you that most ramming materials have low room temperature strength before sintering, and some medium temperature strengths are not high, only when heated to achieve sintering or coking phosphorus compounds in the binder can obtain strong bonds.

Refractory dry ramming mass is granular and powdered material made from refractory raw materials, usually in a loose form with a suitable binder made from reasonable grading and mixing exercises. The refractory dry ramming mass manufacturer tells you that it is similar to dry hard pouring materials, but some do not have no-bake adhesives. Usually, it needs to be constructed by strong ramming, so it is called ramming material.

The refractory dry ramming mass manufacturer tells you that by selecting high-quality refractory raw materials, using the correct ratio and strong ramming, the fire resistance of refractory ramming materials and the corrosion resistance of molten materials can be obtained. The refractory dry ramming mass manufacturer tells you that it has higher stability and corrosion resistance at high temperatures than castables and plastics. However, its service life depends largely on the amount of pre-fire or sintering before first use. If the heating surface is sintered as a whole and does not separate from the bottom layer, the service life can be improved.

Related News

2024-11-05

Zhongzhu New Materials Industry sincerely invites you to participate in the 24th International Forum and Exhibition on Recycled Metals.

WeChat public account

View mobile website

Address : No. 99, Yiqing Road, Gaozi Street, EconomicDevelopment Zone, Dantu District, Zhenjiang City

Fax : +86-511-85683066

E-mail : sales@sfr168.com

Website : https://www.sfr168.com

Copyright©2023 Sino-Foundry Refractory(Jiangsu) Co.,Ltd. Powered by:www.300.cn

Copyright©2023 Sino-Foundry Refractory(Jiangsu) Co.,Ltd.

IPV6 | SEO | Cloud Information