News

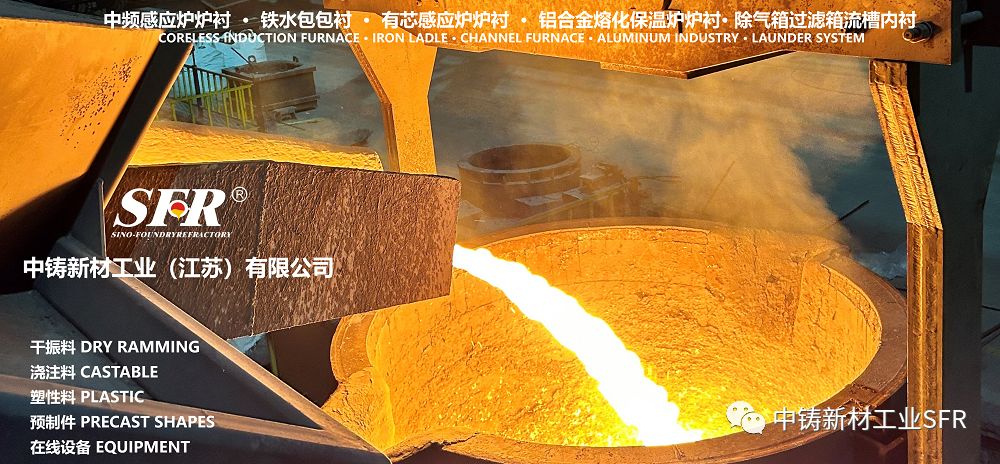

SINO-FOUNDRY—professional refractory manufacturer

Dry Ramming Mass for Steel: Enhancing Furnace Performance and Durability

2026-01-08

Dry ramming mass for steel is a high-density refractory material for furnace and ladle linings, offering durability and thermal shock resistance

View MoreUnderstanding Dry Ramming Mass for Steel Production: Essential Insights for Professionals

2026-01-08

--- Dry ramming mass is an essential refractory material used in the steel production process, particularly when dealing with non-ferrous metals like copper. This specific type of refractory material plays a crucial role in the lining of furnaces, ensuring optimal thermal insulation and resistance to molten metal. As steel production demands high-performance materials, understanding the characteri

View MoreHow Dry Ramming Mass Enhances Efficiency in Steel Plants

2026-01-06

How Dry Ramming Mass Enhances Efficiency in Steel Plants Understanding Dry Ramming Mass and Its Importance in Steel Production The steel industry is a cornerstone of modern infrastructure, offering strength and durability for countless applications. Within this dynamic field, the materials used in manufacturing processes play a pivotal role in determining overall efficiency and quality. One such m

View MoreCommon Mistakes to Avoid When Using Dry Ramming Mass for Copper

2026-01-02

Common Mistakes to Avoid When Using Dry Ramming Mass for Copper Understanding Dry Ramming Mass and Its Importance in Copper Production In the world of metallurgy and copper production, **dry ramming mass** plays a pivotal role. This specialized material is designed to withstand high temperatures and chemical reactions, ensuring the integrity of copper processing. The effectiveness of dry ramming

View MoreUnderstanding Dry Ramming Mass for Copper Applications

2025-12-31

Dry ramming mass for copper is a specialized refractory material used in high-temperature applications, particularly in the metallurgy of copper and other non-ferrous metals. Its primary function is to serve as a lining material in furnaces and other industrial equipment exposed to extreme heat and corrosive environments. Understanding the properties and benefits of dry ramming mass can greatly as

View MoreSINO-FOUNDRY REFRACTORY New Year's Holiday Notice for 2026

2025-12-31

SINO-FOUNDRY REFRACTORY's Holiday Notice for New Year's Day 2026.

View MoreThe Role of Dry Ramming Mass in Enhancing Copper Quality: A Comprehensive Guide

2025-12-29

The Role of Dry Ramming Mass in Enhancing Copper Quality Dry ramming mass is an essential material in the metallurgical industry, particularly in the production of high-quality copper. Its unique properties allow for improved efficiency and enhanced performance in various stages of copper manufacturing. In this article, we will explore the significance of dry ramming mass, its composition, benefit

View MoreUnderstanding Dry Ramming Mass for Copper Applications

2025-12-27

Dry ramming mass for copper is a specialized refractory material primarily used in the metallurgical industry, especially in processes involving the melting and handling of copper. Its formulation is designed to withstand high temperatures and aggressive environments, making it an essential component in the production and processing of copper materials. One of the critical characteristics of dry r

View More

WeChat public account

View mobile website

Address : No. 99, Yiqing Road, Gaozi Street, EconomicDevelopment Zone, Dantu District, Zhenjiang City

Fax : +86-511-85683066

E-mail : sales@sfr168.com

Website : https://www.sfr168.com

Copyright©2023 Sino-Foundry Refractory(Jiangsu) Co.,Ltd. Powered by:www.300.cn

Copyright©2023 Sino-Foundry Refractory(Jiangsu) Co.,Ltd.

IPV6 | SEO | Cloud Information