Foundry Industry

SINO-FOUNDRY—professional refractory manufacturer

Foundry Industry

Refractory for cif melting and holding steel

SFR recommends three types of lining materials for melting steel alloys:

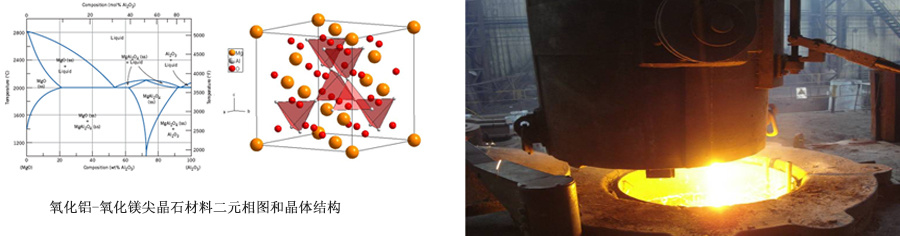

1.STEEL-RAM® neutral ramming materialcorundum spinel based on:

◎ Neutral material, low crack propensity;

◎ The hot surface forms a dense sintered layer of high-strength aluminum-magnesium spinel at high temperature;

◎ The sintered layer can effectively prevent the penetration of high temperature metals, manganese oxide and iron oxide;

◎ The unique design of the product allows the backing to maintain a good loose layer and improve the safety of the whole lining.

◎ The main component of the STEEL-RAM® series is alumina, added with a certain proportion of magnesium oxide and then reacts at high temperatures to form magnesium-aluminum spinel which offers excellent volume stability and high resistance to erosion.

◎ The hot surface forms a dense sintered layer of high-strength aluminum-magnesium spinel at high temperature;

◎ The sintered layer can effectively prevent the penetration of high temperature metals, manganese oxide and iron oxide;

◎ The unique design of the product allows the backing to maintain a good loose layer and improve the safety of the whole lining.

◎ The main component of the STEEL-RAM® series is alumina, added with a certain proportion of magnesium oxide and then reacts at high temperatures to form magnesium-aluminum spinel which offers excellent volume stability and high resistance to erosion.

2.STEEL-RAM® corundum spinel neutral ramming material contains chrome oxide:

◎ This series is based on fused corundum, added with chromium oxide, the fused corundum, magnesia and chrome oxide, forms high corrosion resistance composite spinel, generates a dense sintered layer under high temperature, and having excellent resistance to molten steel erosion while maintaining a good loose layer on the backing which improves the safety of the lining.

3.MAG-RAM® magnesium oxide based ramming material:

◎ Magnesium oxide based materials have excellent resistance to alkaline slag erosion, they are generally used in severe chemical attack working conditions small coreless furnaces (<1000kg) or in , due to their volume stability are not as good as alumina-based materials.

MAG-RAM® series are mainly composed of magnesium oxide, and a certain proportion of alumina is added in order to form magnesium-aluminum spinel under high temperature. This series of materials not only maintains the high corrosion resistance, but also it can reduce the cracking and spalling risk of the lining compared with ordinary magnesium oxide materials.

MAG-RAM® series are mainly composed of magnesium oxide, and a certain proportion of alumina is added in order to form magnesium-aluminum spinel under high temperature. This series of materials not only maintains the high corrosion resistance, but also it can reduce the cracking and spalling risk of the lining compared with ordinary magnesium oxide materials.

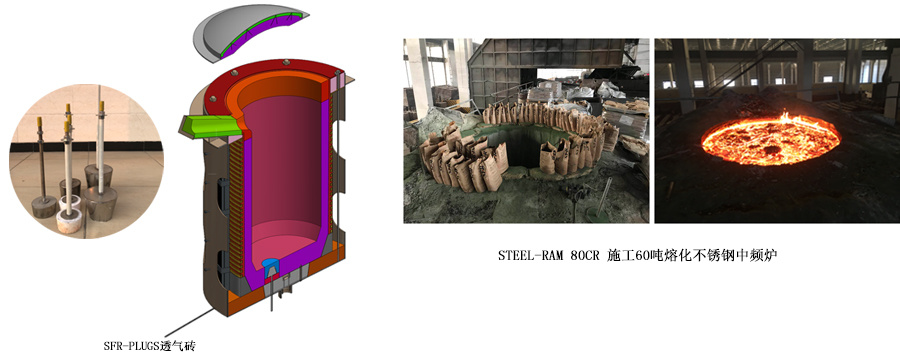

SFR-PLUGS porous plug brick is designed to introduce inert gas into the chamber. This permeable brick is made of refractory material, its unique design can prevent penetration of molten metal but allow the venting of gas. SFR-PLUGS bricks help to homogenize the temperature and chemical composition of the molten metal, and also can make the slag float to the molten metal surface.

Advantages of using SFR-PLUGS bricks:

◆ Reduce the gas content in the molten metal;

◆ Reduce the temperature difference in the furnace;

◆ Reduce the slag inclusion in the molten metal;

◆ Improve the service life of the lining.

| NO. | AREA | PRODUCT NAME | DESCRIIPTION | Al₂O₃ % |

SiO₂ % |

MgO % |

Cr₂O₃ % |

CaO % |

Bulk Density g/cm³ |

Max Temp ℃ |

| 1 | Cover | ULTRA-CAST 200 | Aluminum silicon based castable |

45.0 | 50.0 | 2.0 | 2.30 | 1650 | ||

| 2 | Spout | ALU-PAK® 73CR | Alumina based plastic | 75.0 | 9.0 | 4.0 | 2.85 | 1750 | ||

| ALU-PAK® 78CR | Alumina based added with chromium |

76.0 | 9.0 | 8.0 | 2.95 | 1750 | ||||

| ALU-PAK® 882CR | Alumina based added with chromium |

82.5 | 100 | 2.0 | 2.90 | 1750 | ||||

| 3 | Upper ring | ULTRA-FLO 85 | Alumina based low cement castable |

84.0 | 12.0 | 2.0 | 2.85 | 1800 | ||

| ULTRA-FLO 60 | Mullite based low cement castable |

63.0 | 30.0 | 1.5 | 2.50 | 1700 | ||||

| 4 | Coil grout | COIL CRETE 390 | Alumina based coil grout(White) |

85.0 | 6.0 | 5.0 | 2.60 | 1760 | ||

| COIL CRETE 790 | Tabular alumina based coil grout |

950 | 0.5 | 4.0 | 2.70 | 1800 | ||||

| 5 | Repair | ALU-PAK® 72CP | Alumina based plastic | 75.0 | 9.0 | 4.0 | 2.85 | 1750 | ||

| ALU-PAK® 73CP | Alumina based plastic | 76.4 | 2.5 | 11.0 | 3.15 | 1550 | ||||

| Working lining |

ALU-PAK® 79CR | Alumina based added with chromium | 80.0 | 12.5 | 3.5 | 2.85 | 1850 | |||

| 6 | STEEL-RAM 89 | Dry Ramming Mass Based on Corundum-Magnesia |

88.0 | 0.6 | 11.0 | 3.15 | 1810 | |||

| STEEL-RAM 91 | Dry Ramming Mass Based on Corundum-Magnesia |

67.0 | 0.5 | 32.0 | 2.95 | 1850 | ||||

| STEEL-RAM 92 | Dry Ramming Mass Based on Corundum-Magnesia |

84.5 | 0.2 | 15.0 | 3.10 | 1850 | ||||

| STEEL-RAM 92C | Dry Ramming Mass Based on Corundum-Magnesia |

84.2 | 0.2 | 15.3 | 3.10 | 1850 | ||||

| STEEL-RAM 92H | Corundum based dry-ramming with chrome addition |

84.7 | 0.2 | 14.8 | 3.10 | 1810 | ||||

| STEEL-RAM 80CR | Silica based dry-ramming with chrome addition |

80.0 | 14.5 | 4.5 | 3.05 | 1800 | ||||

| MAG-RAM 96 | Magnesia based dry-ramming mass |

0.8 | 97.0 | 2.85 | 1800 | |||||

| SIL-RAM169CR | Silica based dry-ramming with chrome addition |

0.5 0 | 97.5 | 2.20 | 1700 | |||||

| 7 | Pushing block | ULTRA-FLO 85 | Alumina based low cement castable |

84.00 | 12.00 | 2.0 | 2.85 | 1800 | ||

| 8 | Sliding layer | SFR-MICA | 0.3mm mica paper | 900 |

WeChat public account

View mobile website

Address : No. 99, Yiqing Road, Gaozi Street, EconomicDevelopment Zone, Dantu District, Zhenjiang City

Fax : +86-511-85683066

E-mail : sales@sfr168.com

Website : https://www.sfr168.com

Copyright©2023 Sino-Foundry Refractory(Jiangsu) Co.,Ltd. Powered by:www.300.cn

Copyright©2023 Sino-Foundry Refractory(Jiangsu) Co.,Ltd.

IPV6 | SEO | Cloud Information