Aluminum Industry

SINO-FOUNDRY—professional refractory manufacturer

Aluminum Industry

Selection criteria of Refractories for aluminum industry

SELECTION CRITERIA OF REFRACTORIES FOR ALUMINUM INDUSTRY

Non-wetting & Anti-slag

Low content of SiO2,Fe2O3,CaO

Corrosion resistance of molten aluminum

Thermo-stability

Mechanical strength

Various alloys

In order to slow down growing speed of corundum,and get long service life of refractory,sfr suggest:

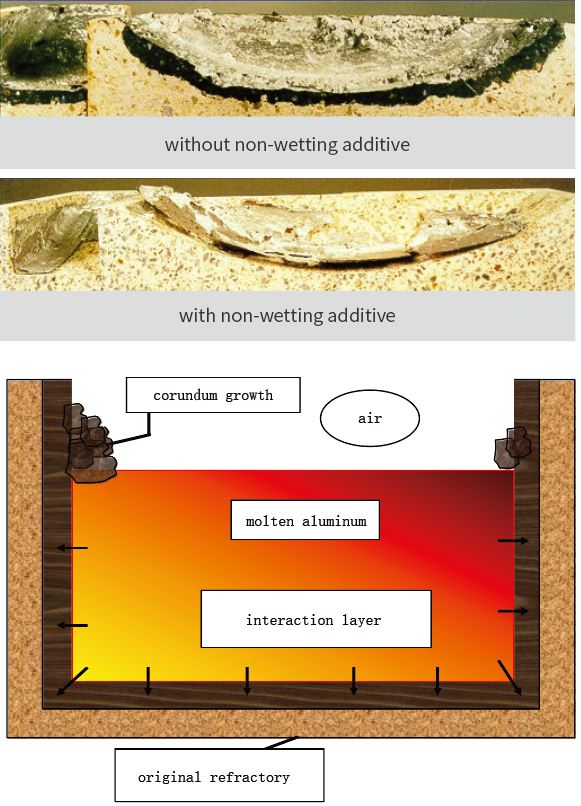

1、Choose material with non-wetting additive

Non-wetting additive works in two aspects :

A、Extend wetting angle, no reaction with aluminum.

B 、Very low porosity after sintering, reduce infiltration of molten aluminum. Two material with same content of alumina,the one has additive shows significant effect of non-wetting property

A、Extend wetting angle, no reaction with aluminum.

B 、Very low porosity after sintering, reduce infiltration of molten aluminum. Two material with same content of alumina,the one has additive shows significant effect of non-wetting property

2、Reduce SiO2 in refractory,especially free SiO2

SiO2 would speed up corundum growth, ALU-FLO 94AR and ALU-FLO 87AR has very low content of SiO2, recommend for demanding area or higher requirements.

3、Select low cement castable

Normal castable needs more water due to high content of CaO, which caused more pores lead to easy aluminum infiltration.Fluxes like Cl/F will react with CaO then destroy inner structure. SFR always recommend low cement castable to minimize porosity, enhancing anti-wetting property.

Refractory lining cracks and spalling, expansion of side wall caused deformation of metal structure, or excess shell temperature, all these are related with corundum growth, reaction as below:

3(Al2O3·SiO2 ) + 4Al →3Si + 5Al2O3

Aluminum reacts with the silicon oxide in refractory, resulting Si increase in molten metal, and Al2O3 increase in lining, introduce volume expansion, it will destroy structure of refractory lining (refer below).

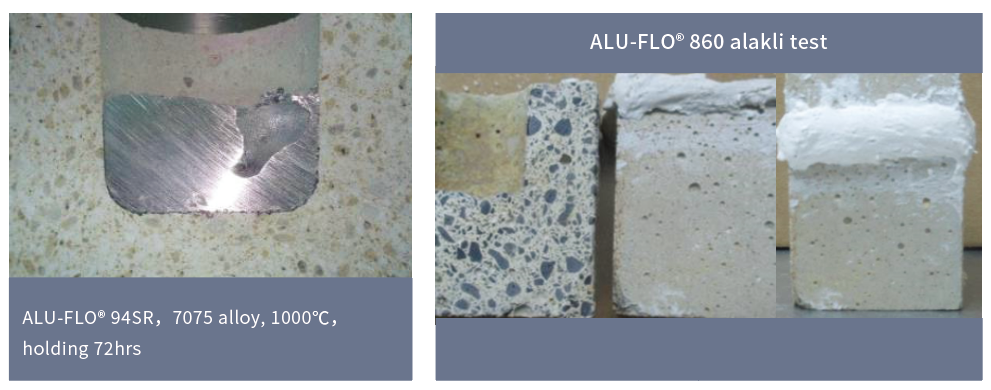

Roof And Upper Wall Alcoa Alkali Test K2CO3 + NaCO3 900oC holding 5hrs

Alkali react with alumina and silicon oxide,forms low melting point phase, reduce service life, carbonates will react with cement hydration product further:

Na2CO3+ CAH10→ CaCO3+Na2O.Al2O3+ 10H2O

SFR designed low cement castable with extremely low impurity(Fe2O3, Na2O),choose new technology of micro powder and water reducer for roof and upper walls.

Both ALU-FLO® 860 and ALU-FLO® 80 has good resistance to alkali attack.

Both ALU-FLO® 860 and ALU-FLO® 80 has good resistance to alkali attack.

WeChat public account

View mobile website

Address : No. 99, Yiqing Road, Gaozi Street, EconomicDevelopment Zone, Dantu District, Zhenjiang City

Fax : +86-511-85683066

E-mail : sales@sfr168.com

Website : https://www.sfr168.com

Copyright©2023 Sino-Foundry Refractory(Jiangsu) Co.,Ltd. Powered by:www.300.cn

Copyright©2023 Sino-Foundry Refractory(Jiangsu) Co.,Ltd.

IPV6 | SEO | Cloud Information